Mastertint Black masterbatches contain furnace type carbon black pigments finely dispersed in thermoplastic polymer carrier resins. Carbon black is the most efficient and economical additive for protecting thermoplastics from ultra violet radiation. It is also a very intense and opaque black pigment. Different carbon black grades are selected to obtain the desired opacity, jetness, and purity or use cost. Some products also contain an exceptionally soft micronised calcium carbonate of high purity, which acts as antiblocking agent, speeds up cooling and lowers use cost.

Quality assurance

All Mastertint Black masterbatches are strictly controlled for carbon black content, dispersion quality, volatiles, bulking density, pellet quality and size in order ensure trouble free processing and top performance.

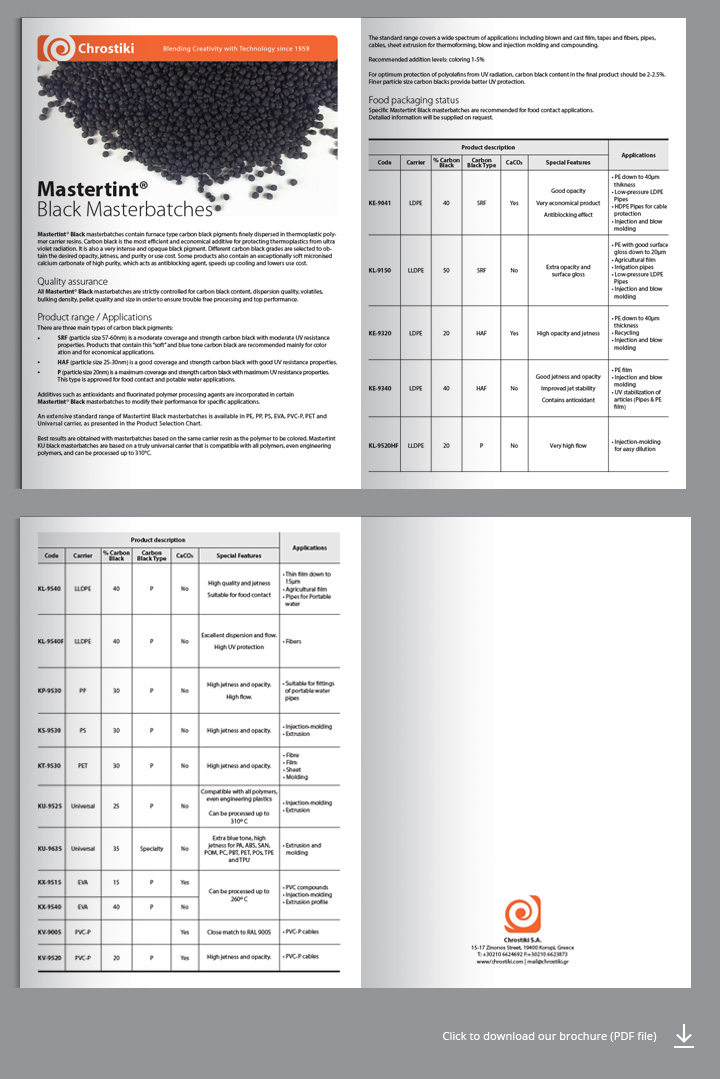

Product range / Applications

There are three main types of carbon black pigments:

- SRF is a medium coverage and strength carbon black with medium UV resistance properties. Products that contain this type are recommended for economical applications.

- RCF is a high coverage and strength carbon black with high UV resistance properties. Products that contain this type are recommended for applications that require extra opacity and surface gloss.

- P is a maximum coverage and strength carbon black with maximum UV resistance properties. This type is approved for food contact and potable water applications. Moreover, products that contain this type are recommended for applications that require maximum opacity and surface gloss.

Additives such as antioxidants and fluorinated polymer processing agents are incorporated in certain Mastertint Black masterbatches to modify their performance for specific applications.

An extensive standard range of Mastertint Black masterbatches is available in PE, PP and PS carrier as presented in the Product Selection Chart.

Best results are obtained with masterbatches based on the same carrier resin as the polymer to be colored. Mastertint Black masterbatches with LDPE carrier may be used to color PP, styrenics, PVC and engineering resins.

Preliminary trials are necessary.

The standard range covers a wide spectrum of applications including blown and cast film, paper coating, extrusion and thermoforming, blow and injection molding and compounding.

Tailor made products can be formulated on request.

Recommended addition levels: coloring 1-5%

For optimum protection of polyolefins from UV radiation, carbon black content in the final product should be 2-2.5%. Finer particle size carbon blacks provide better UV protection.

Food packaging status

Specific Mastertint Black masterbatches are recommended for food contact applications.

Detailed information will be supplied on request.